CNC METAL WORKERS MACHINE LATHE

CNC UE S series

The UE series uses high-efficiency high-power spindle, high-speed servo positioning tower and high-rigidity structure.

In addition, it can be equipped with

high-precision motorized spindle with back

direct drive, high speed spindle

moment or combined with a powerful dome, Y -axis

and an auxiliary spindle to turn into

composite machining center. With perfect

quality and a complete search solution for

processing. The UE series can answer them all

types of processing demand today and in the future.

CNC UE L series

The UE series is a high precision box CNC lathe. The machine tools are made in Taiwan. Its main features are for super heavy cutting. High precision, stability and intelligence!

CNC TC series

Integrated bed structure, powerful cutting ability and a wide range of processing.

CNC lathe with linear guide rotation TZ series

All the main parts of the machine are made of cast iron with strong damping ability. All castings are optimized by Finite Element Analysis (FEA) to reduce distortion and improve damping capability. The reinforcing ribs on the castings of the various lathe series are reinforced to improve rigidity and thermal stability. The rigidity of the compact and symmetrical castings are further improved to ensure high positioning accuracy and repeatable positioning accuracy.

CNC machining center - PG series

The PG series fixed cross rail two-column machining center is a high-precision and high-efficiency machining equipment that incorporates several core component technologies from Japan. This machine has the dual advantages of heavy duty cutting with large rotation and high speed, efficient and precise processing. It is used in automotive, aerospace, shipbuilding, military industry, mold processing and product machining.

CNC machining center - LS series

High-speed two-column machining center with linear motor. It is mainly used for graffiti, molds, 3C, car inspection tools, parts of mechanical construction and other processing requiring high precision. It performs milling, drilling, high-speed screw threading, surface treatment. It achieves extremely good economic indicators.

CNC Machining Center – V Series

V series vertical machining center is mainly used for high precision machining, multi-process and complex profiles, casings and molds. Performs milling, drilling, enlarging, stamping, drilling, turning. Also processes two-dimensional surfaces and inclined surfaces, programmed machining, reduction of machining cycle time. It achieves exceptional economic performance.

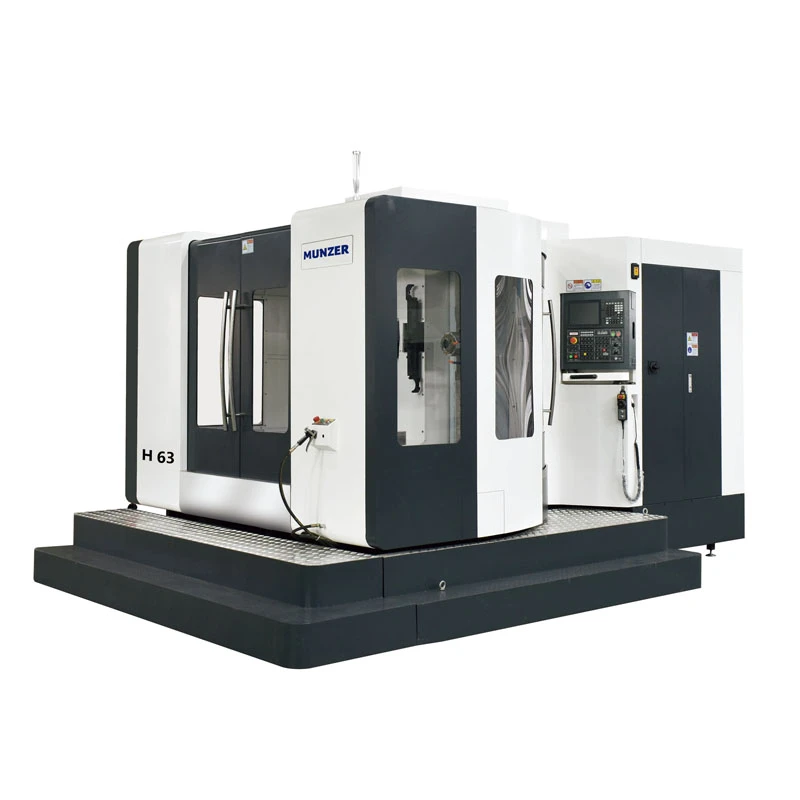

CNC Machining Center – H Series

H series horizontal machining center adopts T type integral base, portal type column with hanging box at the middle point, strong rigidity and good accuracy. It is suitable for precision machining of parts, multi-sided milling, drilling, enlarging, drilling, tapping, etc. The machine is mainly used in the automotive industry, railway transport, aerospace, valve manufacturing, mining industry, textile industry, shipbuilding, electricity and others.

Robot system

Collaborative robots suitable for flexible production: The collaborative robot is a complete implementation of control, servo, encoder, machinery, structure and technology of industrial design. By adapting with external software and hardware, such as thermal actuators, sensors, mobile devices, etc. The UENO robot is good at simplifying complex applications. Suitable for 3C electronics, auto parts, metalworking, control of metal cutting machines, AGV composite applications, electricity, medicine, and other fields.