CNC SYSTEM FOR METAL CUTTING

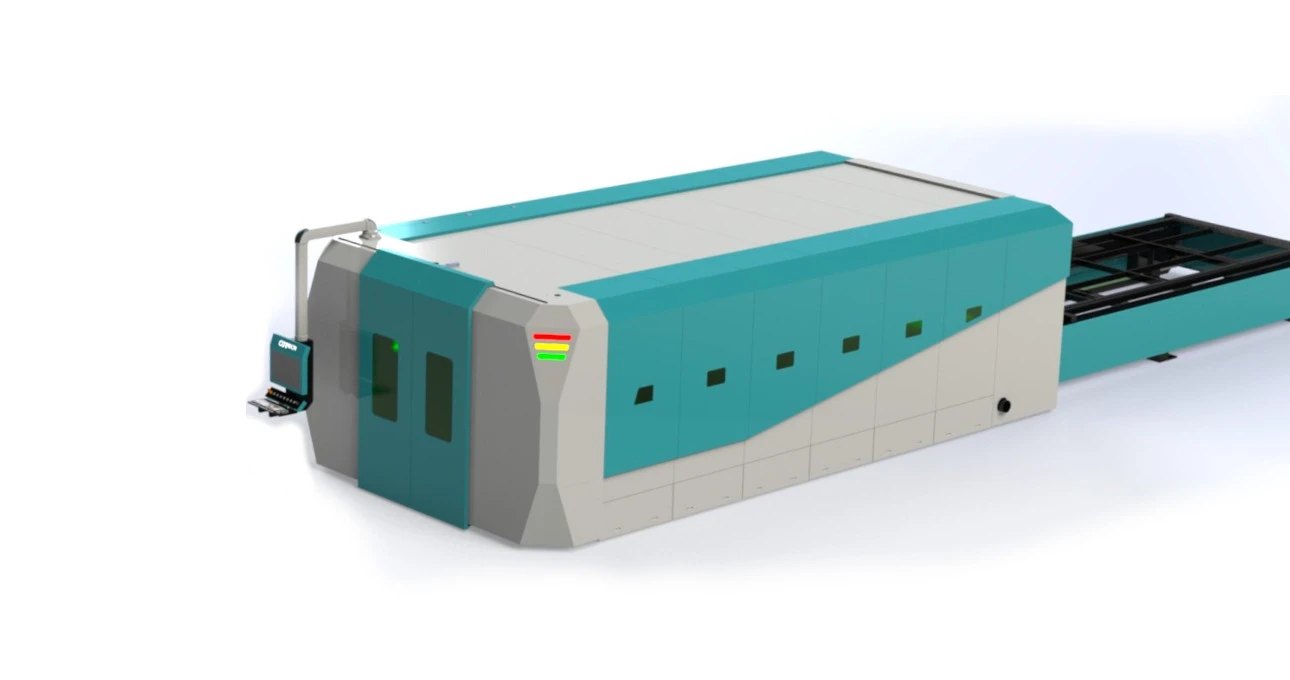

Model L-CUT

laser cutting

Fiber laser technology is the latest advancement in laser cutting. The laser beam is generated with an active fiber and transmitted to the cutting head of the machine via an optical cable. The fiber cutting system is mainly suitable for processing thin to medium sheet metal. It also cuts non-ferrous metals such as copper and brass. Due to their excellent beam quality, fiber lasers are the first choice for various laser precision cutting applications. CUTTECH's fiber laser cutting processes reduce cycle times by providing a faster laser beam at high cutting speeds, especially for thin materials. It is more cost-effective compared to other laser technologies.

Model L-CUT PRO

laser cutting

Fiber laser technology is the latest advancement in laser cutting. The laser beam is generated with an active fiber and transmitted to the cutting head of the machine via an optical cable. The fiber cutting system is mainly suitable for processing thin to medium sheet metal. It also cuts non-ferrous metals such as copper and brass. Due to their excellent beam quality, fiber lasers are the first choice for various laser precision cutting applications. Fiber laser, high processing speed. Cuttech L-CutPro fiber laser cutting processes reduce cycle times by providing a faster laser beam at high cutting speeds, especially for thin materials. It is more cost-effective compared to other laser technologies.

Model C – CUT

plasma cutting

C-Cut is a dynamic, space-saving and easy-to-carry model. The model has a system for ensuring precise cutting with high accuracy. Double sided AC servo motors THC as well as 25mm Helix slide and rack system. With its strong and stable monoblock construction, CompactCut offers a wide range of options, such as HyPerformance Plasma, Hyspeed plasma and air plasma produced by Hypertherm, as well as marking with pen. The compact model is suitable for medium and small businesses.

Model S – CUT

plasma cutting

The S – CUT plasma cutting machine is designed for heavy duty and equipped with a Windows CNC Hypertherm. Thanks to the multiple stations, it provides possibilities for both plasma and oxygen cutting. Thanks to its solid construction, the 35 mm slide and rack system, the double AC servo motors, ensure perfect parallel movement and other components. PRO – CUT increases productivity by minimizing operating costs. The machine is designed for high speed and high precision cutting.

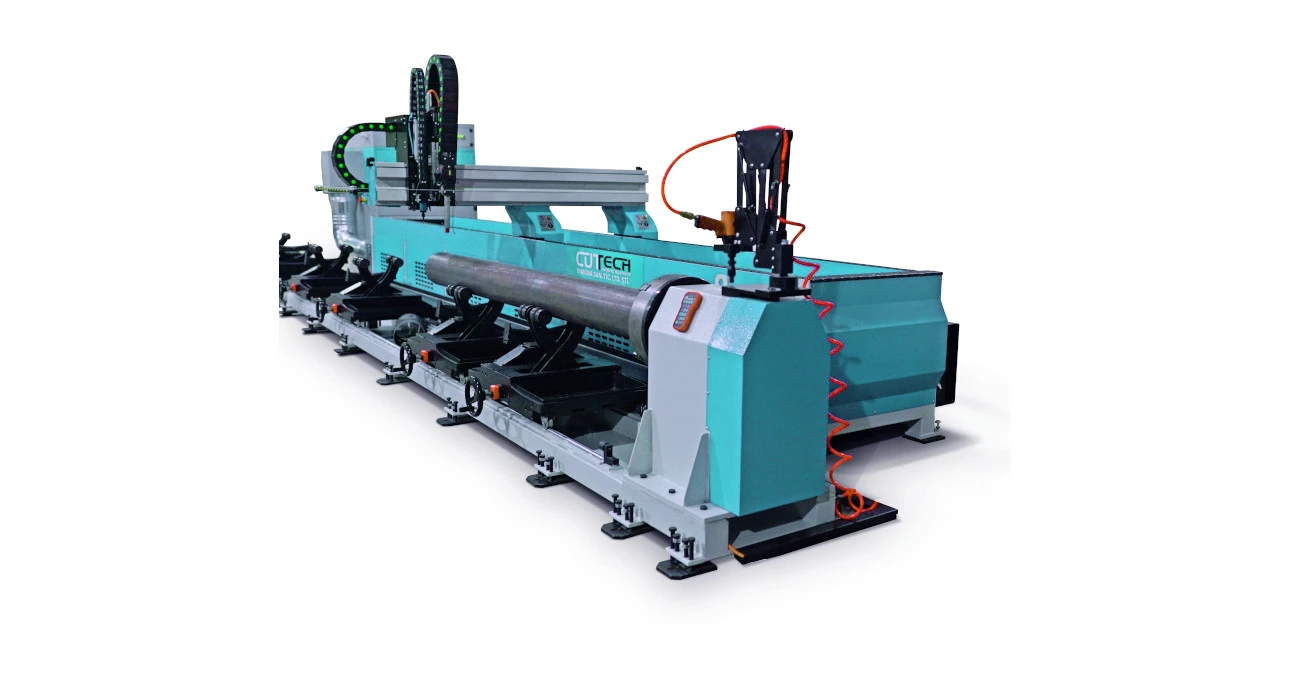

Model PIPE – CUT

plasma cutting

Space-saving and easy-to-move model powered by THC bilateral AC servo motors. Equipped with 25mm spiral linear guides and rack and pinion system to ensure precision cutting with high accuracy. The advanced design, based on high-quality components, perfectly provides the latest plasma and oxygen technologies at an affordable price. As a completely compact machine, it can be moved around the plant, while the pre-assembled delivery significantly reduces start-up time. Covers to protect mechanical parts against smoke and other damage. Smooth running and high angular accuracy is due to the use of high-precision planetary gears.

Model DRILL – CUT plasma cutting

Drilling and cutting the same workpiece.

Automatic tool and oil cooling system.

CNC 15” touch screen.

PanelLinear sliding bridge and Helix Rocks Drive System.

Drilling capacity: Min. Ø M5 Max. Ø M40 (HSS, UDRILL).

Drilling depth: 200 mm.

Touch capacity: min. ØM3 Max. ØM24.

Drilling tool speed: 70-110 m/min.

Drilling speed: 0.15-0.35 mm/rev.

Spindle Speed: 1500 RPM Max.

CNC positioning accuracy: 0.02 mm.

Max. (X&Y) Positioning speed: 15000mm/min.

Bridge traffic control.

Dual gantry AC servo drives.

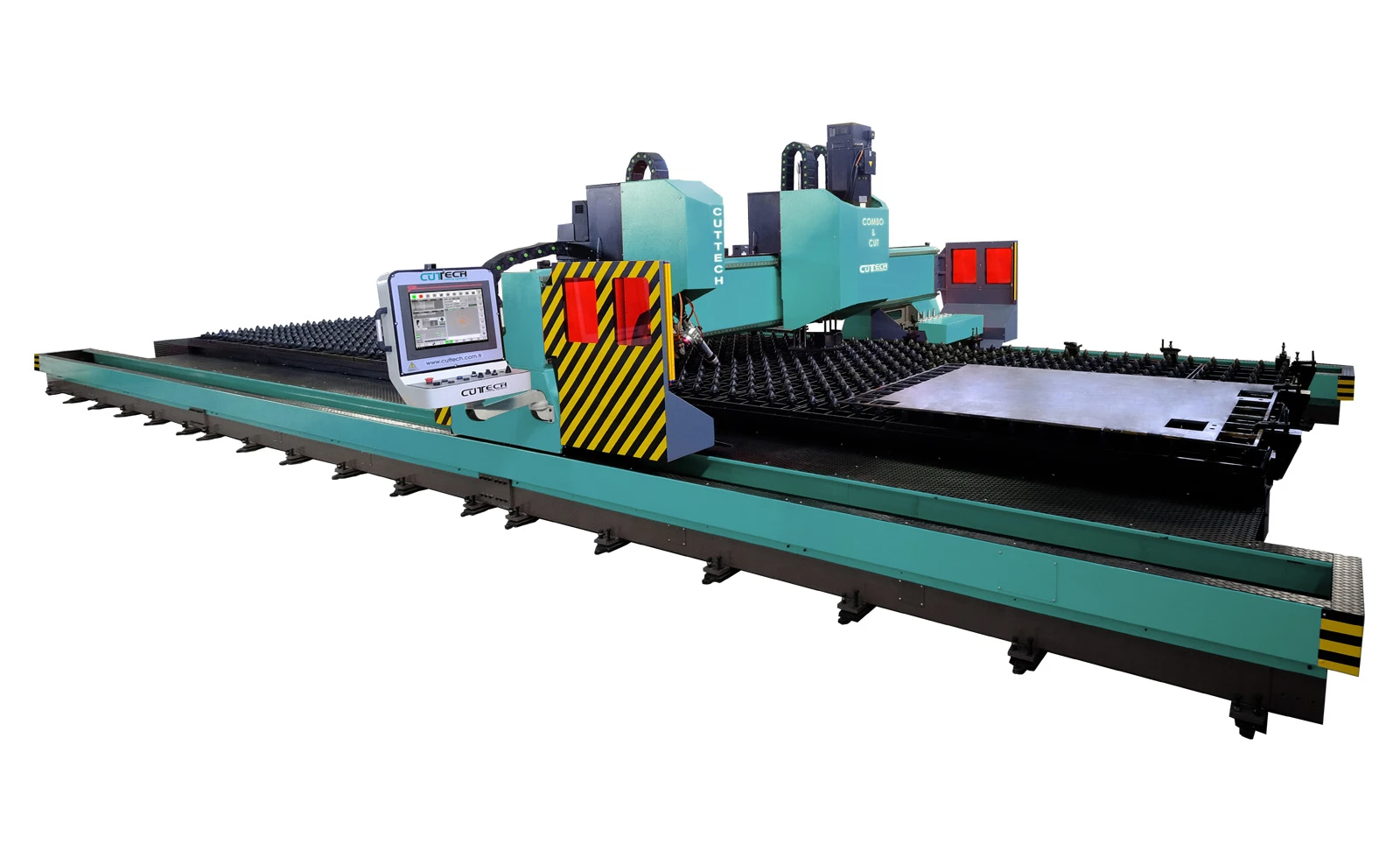

Model PRO – CUT

plasma cutting

The ProCut plasma cutting machine is designed for heavy duty and provides both plasma and oxygen cutting capabilities thanks to its multi-station operation. Small holes, perfect internal and external contours: Precision Contour Cut revolutionizes plasma cutting. With its robust one-piece structure, the C-Cut offers great advantages to users thanks to its features such as HyPerformance Plasma, HySpeed Plasma and Air Plasma produced by Hypertherm, as well as pen marking.